In this page we offer the part numbers for inner parts for the engine Develon/Doosan/Daewoo Engine model DE08TIS with the fitting quantity and unit weight for each part also the wear limits for change the used part with the new one , for wear limits only click on the part number, Always remember that El-Rayah always give your the best information you need as well as best parts quality

| Seq. | Part Number | Description | Fit QT’Y | Weight | Replaceable part |

| 1 | 65.01201-0050 | LINER;CYLINDER | 6 | 1.2 | |

| 2 | 65.02501-0228B | PISTON | 6 | 1.75 | |

| 3 | 65.02503-8146 | PISTON RING KIT | 1 | 0.58 | |

| 4 | 65.02502-0010 | PIN;PISTON 42X20X95 | 6 | 0.78 | |

| 5 | 06.29020-0126 | RING;SNAP 42X1.75 | 12 | 0.01 | |

| 6 | 65.03201-1011A | GUIDE,VALVE | 12 | 0.05 | 65.03201-1061 |

| 7 | 65.03203-1028D | RING;VALVE SEAT EXHAUST | 6 | 0.03 | |

| 8 | 65.03203-1029G | RING;VALVE SEAT INTAKE | 6 | 0.03 | |

| 9 | 65.04101-0041 | VALVE;INTAKE | 6 | 0.18 | |

| 10 | 65.04101-0042 | VALVE;EXHAUST | 6 | 0.18 | |

| 11 | 65.04902-0013 | SEAL;VALVE STEAM | 12 | 0.01 | |

| 12 | 65.04410-0017 | . BUSH;CAM SHAFT | 4 | 0.13 | |

| 13 | 65.02405-0010 | . BUSH;CON-ROD | 6 | 0.12 | 65.02405-1011 |

| 14 | 65.01110-6351 | BEARING;MAIN STD | 7 | 0.21 | 140103-00075 |

| 15 | 65.01150-0015 | BEARING;THRUST UPPER | 2 | 0.03 | 120816-00083A |

| 16 | 65.01150-0016A | WASHER;THRUST LOWER | 2 | 0.03 | 120816-00084A |

| 17 | 65.02410-0010 | BEARING;CON-ROD(STD) | 6 | 0.14 | |

| 18 | 65.01510-0157 | SEAL;OIL | 1 | 401106-00217 | |

| 19 | 65.01510-0037 | SEAL;OIL REAR | 1 | ||

| 20 | 65.03901-0058A | GASKET;CYLINDER HEAD | 3 | 0.1 | |

| 21 | 65.00900-1146S | GASKET HALF SET | 1 | ||

| 22 | 65.99601-8034 | OVER HAUL GASKET KIT-ALL | 1 | 2.75 | 400632-00080 |

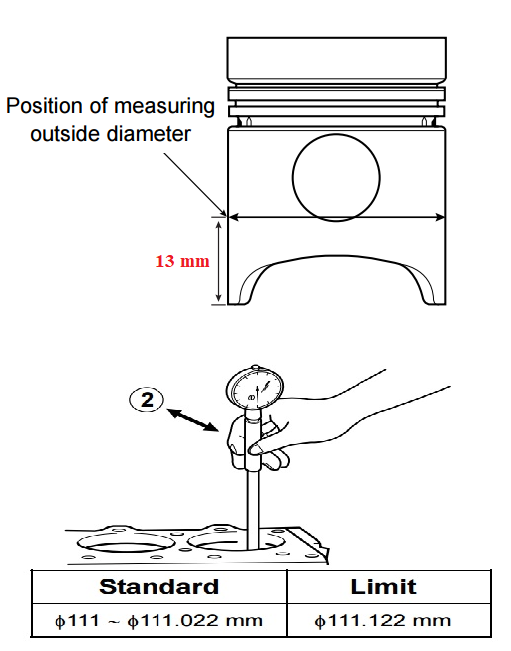

Cylinder liner 65.01201-0050

In order to choose the right liner for your engine, You have to Measure unworn portion beneath the rim of the upper side.The standard value of the liner inside diameter is φ111~φ111.022 and the wear limit for use is φ111.122 , If your liner exceed the wear limit you have to replace it with a new one

Piston inspection 65.02501-0228B

- Clearance between the piston and cylinder

With an outside micrometer,measure the piston outside diameter at a point 13mm away from the lower end of piston skirt in a direction at a right angle to the piston pin hole.

Standard φ110.883 ∼ φ110.897 mm

Using a cylinder bore gauge, measure cylinder liner inside

diameter at 3 points (cylinder top ring contacting face, middle, and oil ring contacting face on BDC) in a direction at an angle of 45°. Take the mean value with the largest and smallest values excepted.

Standard φ111 ∼ φ111.022 mm Limit φ111.122 mm

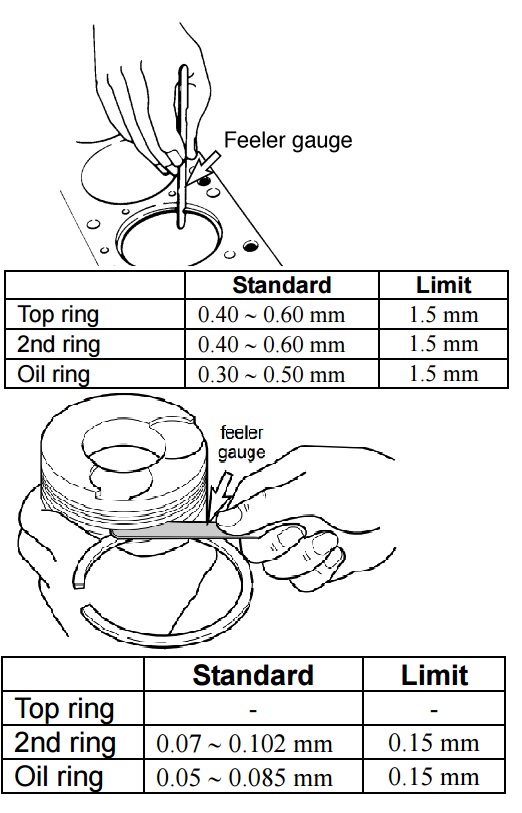

PISTON RING SPECS

- Visual check

- Replace the piston rings with new ones if detected worn or broken when the engine is overhauled.

- Piston ring gap

- Insert the piston ring into the upper

portion of the cylinder liner bore so

that it is held at a right angle to the

cylinder liner wall.

Measure the piston ring gap with a

feeler gauge.

- Insert the piston ring into the upper

- Piston ring side clearance

- Fit the compression ring and oil ring in

the piston ring groove.

With a feeler gauge, measure side

clearance of each ring, and replace

either the ring or piston if the measured

value is beyond the specified limit.

- Fit the compression ring and oil ring in

- Piston ring tension

- With a tension tester, measure piston ring tension. Replace the piston ring if the measured value is beyond the limit.

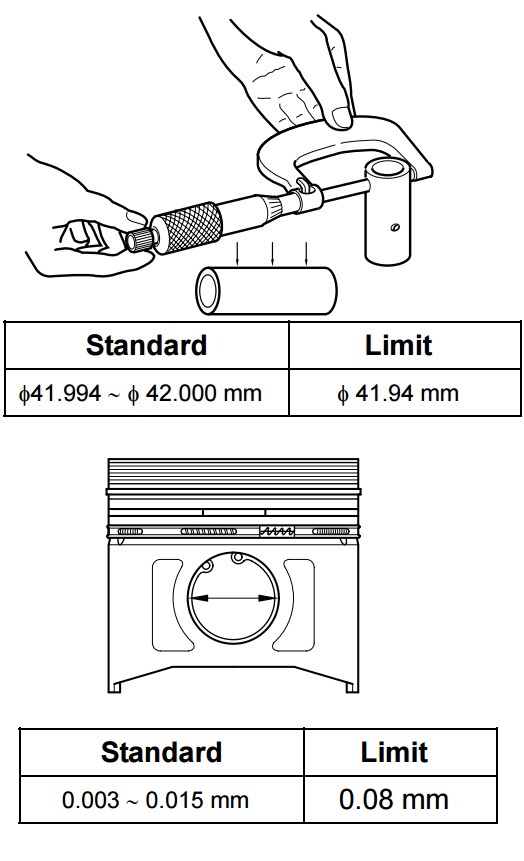

Piston Pin

- wear

- Measure the amount of wear on the

piston pin at the points as shown. The

measured values are beyond the limit

(0.08 mm or greater), replace the pin.

- Measure the amount of wear on the

- Clearance

- Measure the clearance between the piston pin and connecting rod bushing,and replace either of them, whichever damaged more, if the measured value is beyond the limit.

- Condition check

- Check the engaged condition of the piston and piston pin. If it is possible to force the pin into the piston heated with piston heater, the piston is normal. When replacing the piston, be sure to replace the piston pin together.

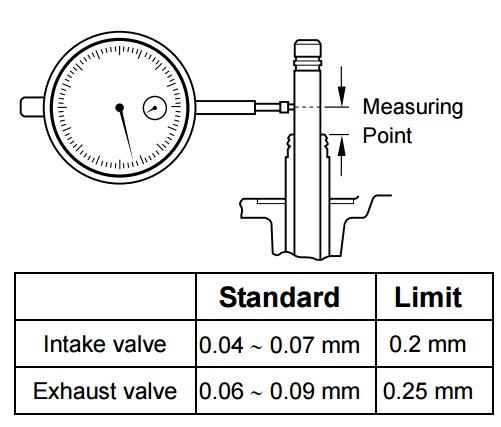

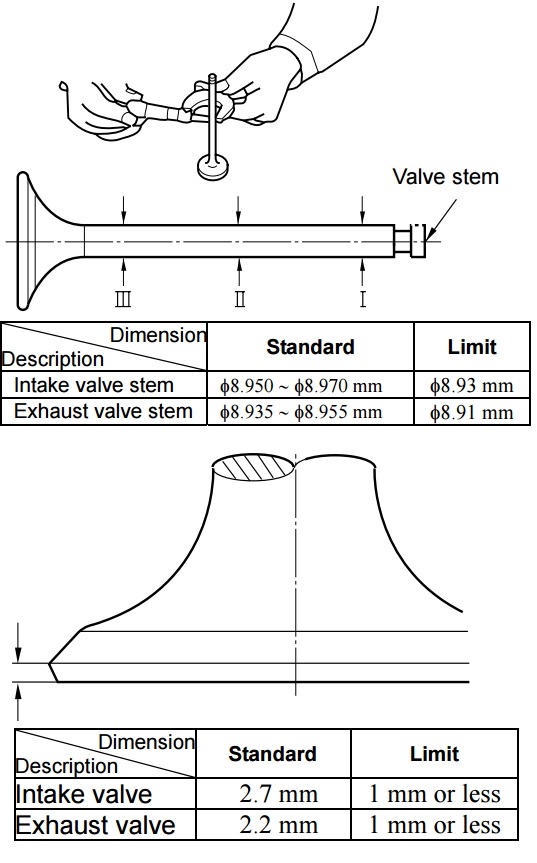

Intake and exhaust valve

- Valve stem outer diameter

- Measure the valve stem outer diameter at 3 positions (top, middle, and bottom), and check for any wear and if beyond the limit value, replace the valve.

- Valve seat contacting faces

- Check the valve seat contact surface for any crack and wear, and if necessary, correct with grinding paper, and if excessive, replace it.

- Valve head thickness

- Measure the thickness of valve head and if beyond the limit value, replace the valve

1.Valve guide

Insert a valve into cylinder head and

measure the clearance between

valve guide and valve by valve

movement. If the clearance is

excessive, measure the valve and

replace the excessively worn valve